ALMIG COMPRESSORS

Northwest Compressors are the North West’s leading service provider for the supply and service of Almig Compressors and Compressed Air Equipment to a wide variety of clients in both the North West and the UK alike.

COMBI series screw compressor

Our COMBI product range of screw compressors is the cost-effective 4-in-1 solution from ALMiG. The compressed air station combines a compressor, compressed air receiver (with autom. condensate drain as an option, otherwise manual shut-off), refrigeration dryer and pre- and after-filter * in one housing as standard and therefore satisfies the stringent compressed air quality requirements for pneumatic applications according to DIN ISO 8573-1.

The COMBI screw compressors deliver 3 – 22 kW of power with volume flows of 0.21 – 3.34 m³/min and are fitted with a reliable and highly effective V-belt drive. Requiring a small space of 1 m² and emitting very low noise levels, the compact compressors can be installed exactly where the compressed air is needed, saving your company major investments in expensive pressure lines. Other benefits of these very compact compressors are their low weight and ease of transport. All it takes is one lifting truck or fork-lift truck to position the complete compressed air station.

Contact Us for more information

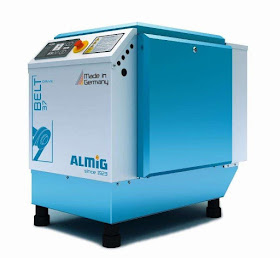

BELT series screw compressor

The BELT 4 – 200 series ensures your company benefits from a high compressor output and reliability at minimum operating costs around the clock. The tenacious compressors are fitted with a low-maintenance V-belt drive, which transfers the 4 – 200 kW of power with virtually no losses. This means that the compressor makes full use of the motor’s output.

The BELT 4 – 200 series enables very cost-effective and reliable usage in a volume flow range of up to 30.52 m³/min. The fixed speed concept of the BELT series also delivers long service lives and low maintenance costs, making thescrew compressors especially well suited for use as base load compressors.

Contact Us for more information

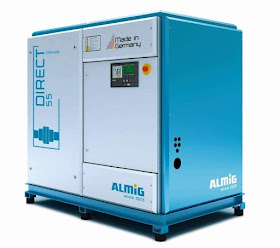

DIRECT series screw compressor

The brand new design of the DIRECT series of screw compressors enables ALMiG to set new standards in the world of compressed air systems with direct drive.

In this instance, direct drive means that the motor’s output is transferred directly to the compressor stage without any loss by means of a v-belt or gear drive.

This type of drive is around 99.9 % efficient, i.e. much more efficient than standard drives: Even more compressed air from even less electric energy – around the clock.

The unique design concept of the DIRECT series makes it incredibly cost-effective in every kW class and therefore highly versatile. When these compressors with direct drive are combined with the VARIABLE series, they make an unbeatable energy-saving duo. Both compressed air systems have an identical design but the screw compressors of the VARIABLE product range also have a frequency converter.

Contact Us for more information

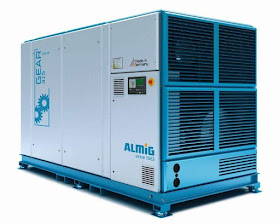

GEAR series screw compressors

The compressed air systems of the GEAR series allow ALMiG to supply a new generation of screw compressors for very high compressed air requirements. The product range includes delivery volumes of 3.58 – 71.15 m³/min at max. operating pressures of 8, 10 and 13 bar.

The maintenance- and service-friendly drive concept of the GEAR compressors includes a robust drive motor with high power reserves and flexible, well balanced couplings with interchangeable operating elements. The concept delivers minimum slip, high reliability, is virtually free of losses with an efficiency of > 98% and is gentle on the drive. What’s more, highly efficient separation of the cooling medium enables a minimum residual oil content of just 2–3 mg/m³.

Contact Us for more information

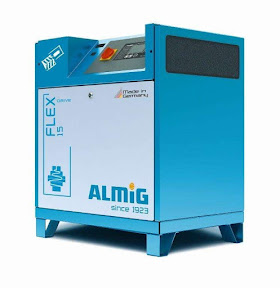

FLEX series screw compressor

The speed-controlled, directly driven compressors of the FLEX series are based on cutting edge research and technology and are used wherever compressed air is to be generated by a small, compact and extremely quiet system. Because of the integrated single-shaft solution, the sound level of these small screw compressors is around 60 dB(A), allowing them to be used directly in the workplace.

Market analyses show that on average compressors only have a utilisation rate of around 50–70 %. The maximum delivery volume is, however, only needed during peak times.

The integrated ALMiG SCD technology therefore delivers an integral drive concept with maximum cost-effectiveness forSpeed Control and Direct drive.

Contact Us for more information

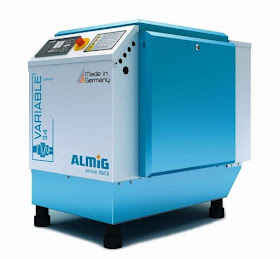

VARIABLE series screw compressor

The speed-controlled screw compressors of the VARIABLE series have been developed with the latest knowledge drawn from research and technology for applications with variable compressed air requirements.

Market analyses show that on average compressors only have a utilisation rate of around 50–70 %. The maximum delivery volume is, however, only needed during peak times. So we developed ALMiG SCD technology, the benefits of which come to the fore in partial load applications – i.e. exactly where they are needed.

SCD technology stands for Speed Controlled and Direct drive and is an integral drive concept with maximum cost-effectiveness.

Contact Us for more information

LENTO series screw compressor – Oil Free

Screw compressors of the oil-free LENTO series deliver maximum cost-effectiveness in compressed air treatment by precisely matching the volume flow to the exact compressed air requirement and through low compressed air outlet temperatures and minimised service and maintenance costs.

Not only is there demand for high-quality, 100 % oil-free compressed air in the pharmaceutical, foodstuffs, electrical engineering and medical industries, but wherever products of the highest quality are produced. Therefore ALMiG’s oil-free compressors of the LENTO series deliver maximum compressed air quality in highly sensitive areas of use.

Only water, the most natural of all raw materials, is used in the compression process.